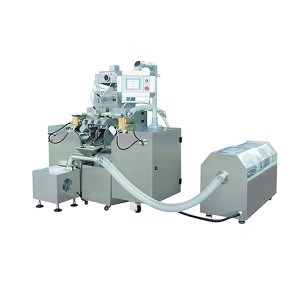

I-NJP Series Automatic Capsule Filling Machine

Amaphilisi ku-hopper yezinto ezibonakalayo azohlala emile engena kudivayisi yokuthumela emshinini wokuhlukanisa lapho umshini uqala ukusebenza.Emphumeleni wokuqondisa ukusunduza nokuthumela idivayisi, i-capsule ngayinye izobekwa ku-module bores yesikhundla sokuqala sokusebenza, isikhundla sesibili sokusebenza kanye nesikhundla sesithathu sokusebenza ngendlela ye-cap up body down, okwamanje, uhlelo lokuhlukanisa i-vacuum luzohlukanisa i-cap nomzimba. .Indawo yesine yokusebenza yindawo egcinelwe isithungu.Esimeni sokusebenza sesihlanu, imojula ephezulu iyakhuphuka, ngaphandle kwemojuli ephansi.Idivayisi yokugcwalisa izophusha okusanhlamvu okucindezelwe ku-capsule endaweni yokusebenza yesithupha.Indawo yesikhombisa yokusebenza yindawo egcinelwe ikhamera ye-buffer.Lawo maphilisi ikepisi nomzimba okungazange kuhlukaniswe azokhishwa endaweni yesishiyagalombili yokusebenza.Indawo yesishiyagalolunye yokusebenza iyafana neyesine yokusebenza.Esimeni sokusebenza seshumi, imojula ephansi ihoxisiwe futhi ihlanganiswe nemodyuli ephezulu, ukubopha nokukhiya amaphilisi okugcwalisa kumphumela we-push rod, finyelela imfuneko yomkhiqizo oqediwe.Esimeni sokusebenza seshumi nanye, amaphilisi okuqinisa i-prefect azophushwa ngenduku yokusunduza bese eqoqa.Esimeni sokusebenza seshumi nambili, hlanza idivayisi hlanza imojuli futhi ilungele ukungena ekuzukisweni okulandelayo.

1. Yamukela umklamo wesizukulwane sesibili ovaleleke ngokuphelele.I-upper die ithatha ama-shafts amabili ukuya phezulu naphansi ngokuzungeza, kanye nezigxivizo zejeli ye-silica ukuze kuncishiswe ukudla okuyimpushana ukungena nokuphuma kwetafula elijikelezayo;i-low die ithatha ama-shafts amabili ukuze ihambe futhi iphume ngokuzungezile, ifaniswe nezigxivizo zenjoloba ezivela kwamanye amazwe ukuze kuncishiswe isimo sokuphakelwa kwempushana ngenxa yokunwetshwa emuva naphambili kwe-shaft ehambayo, futhi izinzile futhi inokunemba okuphezulu;ama-shafts aphindwe kabili ayenziwe ngekhava yokunyathelisa, kulula ukuhlakazeka nokuhlanganisa, kulula ukuyihlanza, futhi indandatho yokufaka uphawu ayishintshiwe.Kuyadingeka ukuvula i-turntable ukuze ugweme amaphutha amakhulu ngenxa yokuhlakazwa kwe-turntable.

2. Yamukela izingxenye ezintathu zokulawula;futhi ithatha umthamo ongaphansi komhlaba njengesisekelo, ukuze kuqedwe ukuguqulwa okuvuthiwe kwe-dosing disc kanye nesoso yethusi, ifana ngesikhawu futhi iqinisekisa ukunemba kwesisindo sokugcwalisa, kunciphisa izenzakalo zokuvuza kwempushana futhi kulula ukuyihlanza.

3. Isebenzisa i-capsule vacuum positioning machanism ukwenza i-capsule ifaneleke ngaphezu kwama-98%.

4. Engeza umsebenzi owengeziwe we-Capsule control switch.Lawula i-capsule ngaphandle komshini: iphephe kakhulu futhi ngokushesha.

5. Indlela yokugcwalisa i-powder evaliwe ye-modular iyamukelwa, okulula ukuhlanganisa nokuhlakaza futhi kulula ukuyihlanza.

1. Shintsha ngokuzenzakalelayo isiqondiso sesakhiwo se-capsule.

2. Ukuhlukaniswa kwe-capsule kusebenzisa indlela ye-vacuum suction capsule body, futhi isakhiwo se-buffer yakhelwe ukunciphisa ukulahlekelwa nomsindo.

3. I-plug-type metering kanye nedivayisi yokugcwalisa ye-powder, i-slider-type metering kanye nedivayisi yokugcwalisa yama-pellets.

4. Isiteshi senduku yokugcwalisa samukela umklamo we-modular, okulula ukuhlakazeka nokushintshwa, futhi umakwe ngesilinganiso sokulungisa ivolumu yokugcwalisa.

5. Akukho mpahla esele kumgodi wokuphakelayo, okunciphisa udoti.

6. Uma i-viscosity yezinto ezibonakalayo iphezulu, izinto ezibonakalayo ku-punch rod zingasulwa ngokulungisa ikhamera ukuze kuncishiswe ukunamathela nokushaya.

7. Izindandatho zokuvala ezisezingeni eliphezulu ezenziwe ngokwezifiso zinciphisa kakhulu igebe lokunyakaza lokungena kwe-powder, futhi zonke izindandatho zokuvala zingahlakazwa kalula futhi zishintshwe ngokuzimela.

8.Ishubhu Lokukhipha Uthuli Olufihliwe: kunciphisa uthuli nobuhle

| Imodeli | I-NJP-200 | I-NJP-400 | I-NJP-800 | I-NJP-1200 | I-NJP-2300 | I-NJP-3500 |

| Amandla(Amaphilisi/h) | 12000 | 24000 | 48000 | 72000 | 138000 | 210000 |

| Isisindo somshini(kg) | 700 | 800 | 900 | 1100 | 1500 | 2200 |

| Ubukhulu Sebonke(mm) | 610*680*1800 | 760*780*1800 | 840*820*1900 | 860*940*1900 | 1010*1080*2000 | 1170*1560*2000 |

| Ukunikezwa kwamandla kagesi | 380/220V 50Hz | 380/220V 50Hz | 380/220V 50Hz | 380/220V 50Hz | 380/220V 50Hz | 380/220V 50Hz |

| Amandla Aphelele(KW) | 3 | 3 | 4 | 5 | 8 | 10.5 |

| Inombolo Yengxenye Yezibhobo | 2 | 3 | 6 | 9 | 18 | 25 |

| Vacuum | 20m^3/h-0.04-0.08Mpa | 40m^3/h-0.04-0.08Mpa | 63m^3/h-0.04-0.08Mpa | 120m^3/h-0.04-0.08Mpa | ||

| Ukwenza Isilinganiso | I-capsule engenalutho 100%Igcwele, i-capsule engaphezu kuka-99% | |||||

| Ifanele iCapsule | 00,0,1,2,3,4,5# | |||||

| Iphutha Lokugcwalisa | ±2.5%-±3.5% | |||||