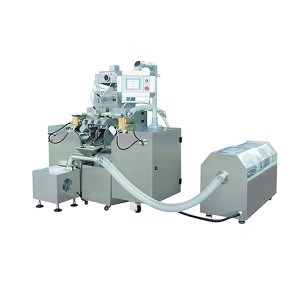

CGN-208D Semi-Automatic Capsule Filling Machine

Ilungele ukugcwalisa i-powder nezinto eziyimbudumbudu ekhemisi nasembonini yokudla yezempilo.

Lo mshini unesiteshi esizimele sokuphakela i-capsule engenalutho, isiteshi sokudla okuyimpushana kanye nesiteshi sokuvala ama-capsule.Inqubo ephakathi idinga ukucutshungulwa ngesandla.Umshini usebenzisa ukulawulwa kwesivinini esiguquguqukayo, ukusebenza kulula kakhulu futhi kulula, futhi okuphakelayo kwe-powder impahla ngendlela efanele.Umzimba womshini kanye netafula lokusebenza zisebenzisa impahla ye-SS;ukuhlangabezana nezidingo zenhlanzeko zasekhemisi.

Le mishini ifanele ukugcwaliswa kwe-capsule ye-powder nezinto ze-granular embonini yezemithi nokudla kwezempilo.Umshini usebenzisa ukulawulwa kwesivinini esiguquguqukayo, ukusebenza kulula kakhulu, ukuphakela kulungile, futhi kuhlangabezana nezidingo ze-GMP.Lesi yisinqumo esihle kakhulu sokugcwalisa i-capsule.

Kusetshenziswa uhlelo lokulawula uhlelo, ukusebenza kwephaneli yokuthinta, ukulawulwa kwesivinini sokuguqula imvamisa engenazinyathelo, ukulawula umoya, kanye nedivayisi yokubala okuzenzakalelayo ye-elekthronikhi kungaqedela ngokuzenzakalelayo ukubeka, ukuhlukanisa, ukugcwalisa, ukukhiya kanye nokunye ukusebenza kwe-capsule, futhi ulungise isisindo sokugcwalisa se-powder. .Kokubili umzimba kanye nendawo yokusebenza yenziwe ngensimbi engagqwali yekhwalithi ephezulu, enenani elinembile lokugcwalisa nokusebenza okulula.Ifanele ukugcwalisa ama-capsules we-powder, granule kanye nemikhiqizo yokunakekelwa kwezempilo.

1. Umshini, ugesi, negesi kuhlanganisiwe, futhi umshini kulula ukuhlukanisa imisebenzi efana nokufaka, ukuhlukanisa, ukugcwalisa, nokukhiya ama-capsules.

2. Umshini wokuphakela i-capsule othomathikhi oqondisayo unomklamo ofanayo nomshini wokugcwalisa i-capsule othomathikhi, futhi ulawulwa yi-converter frequency.Isembozo somshini, iphaneli yokusebenza kanye ne-capsule feeder engenalutho zonke zenziwe ngensimbi engagqwali, ehlangabezana nezidingo zenhlanzeko zekhemisi futhi igwema ukungcoliswa kwethusi kwezinto.

3. Thinta inkinobho, i-propeller yokuphakelayo, kanye ne-turntable yokugcwalisa ingasebenza ngokuzenzakalelayo ngokusho kokusetha ngaphambilini kanye nokulawulwa kwesivinini sokuguqulwa kwemvamisa.

4. Ukwehliswa kwezindleko zokupakisha ngenxa yokusetshenziswa okuphezulu nokuqhubeka.

5. Alikho ibhokisi legiya lendabuko, isakhiwo esilula nokugcinwa okulula.

6. Gcina ibhalansi yevolumu yokugcwalisa ezinhlangothini zombili.

7. Ipompo ye-vacuum kanye ne-compressor yomoya kunikezwa njengezesekeli ezijwayelekile.

| Isikhathi Sokushintsha Isikhunta Sokulungisa Amaphutha | 5-8mins(yabaqalayo) |

| Izinga Lokukhiqiza | 1-2.5 izinkulungwane eziyishumi/ihora (kuye ngokuthi amaphilisi No.) |

| Amaphilisi Asebenzayo | 000#,00L#,00#,0#,1#,2#,3#,4#,Mechanism amaphilisi ajwayelekile |

| Ukugcwalisa Material | Ngaphandle kwempushana enamathelayo nemanzi, ama-granules amancane |

| Amandla Aphelele | 4.0kw |

| Ingcindezi Yomoya | 0.03m^3/min 0.6Mpa |

| Iphampu yeVacuum | Umthamo wepompo ngu-40m^3/h |

| Ubukhulu bomshini | 1140*700*1630mm |

| Ukupakisha Dimension | 1650*800*1750mm |

| Isisindo sengqikithi | 350kg |

| Isisindo esikhulu | 380kg |